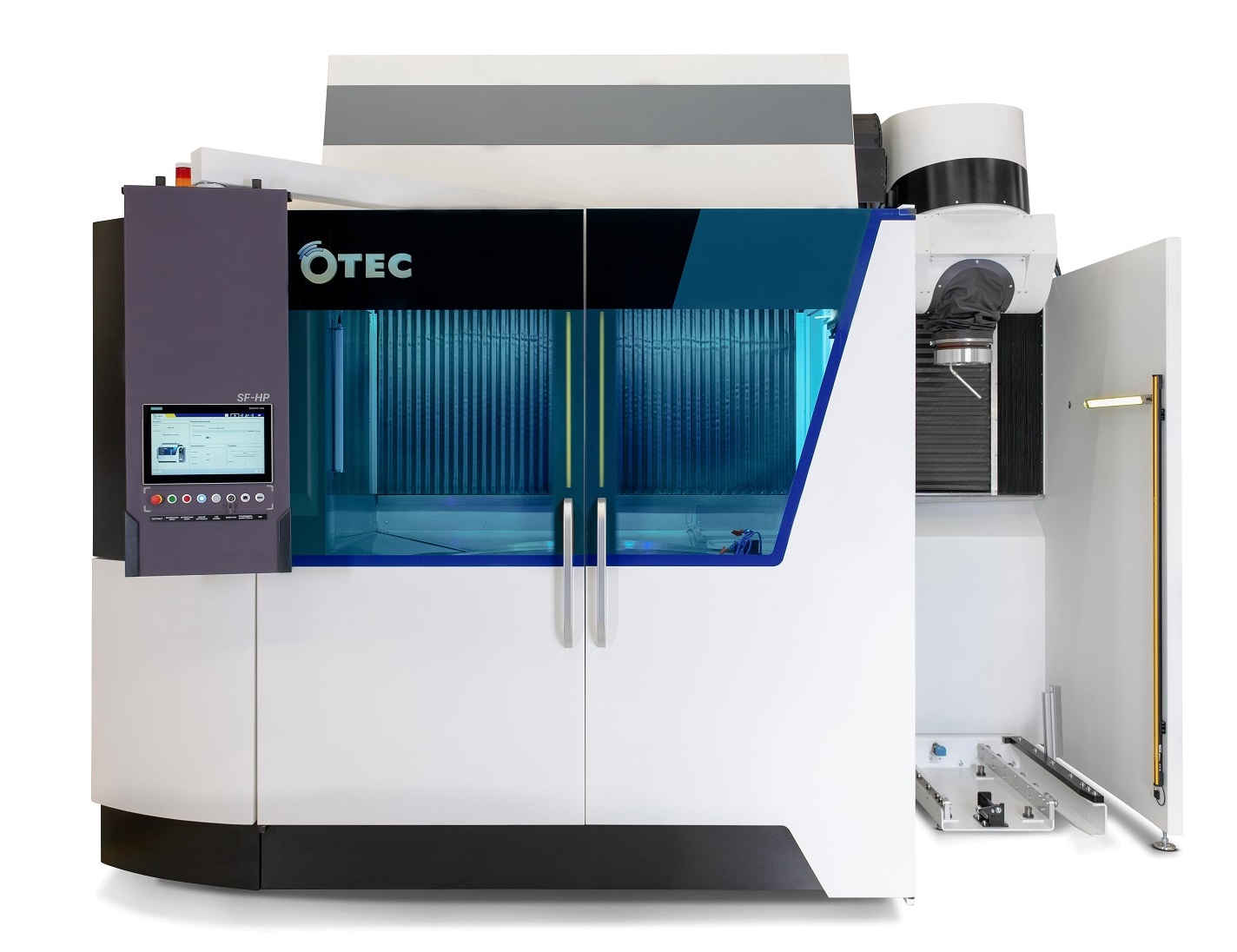

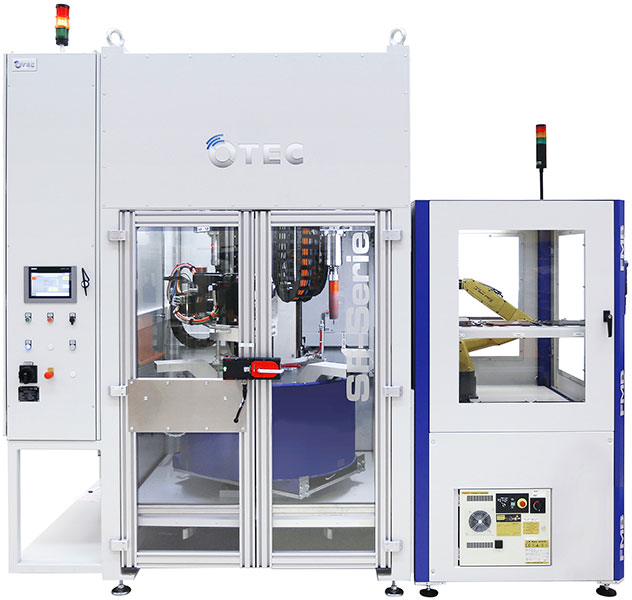

Over a period of several years, OTEC Präzisionsfinish GmbH has developed special parameters for the drag finishing and disc finishing processes in order to ensure fast and cost-effective surface finishing and consistently high quality. Whether for finishing prosthetic items, implants or medical equipment, OTEC is on hand to ensure that you benefit from reliable results and expert customization.

To protect patients from infection by pathogens and assure functionality of the different medical instruments and implants, cleaning medical products and contact lenses is of great importance already during and after the manufacturing process. Surgical instruments as well as metal, ceramic or plastic instruments must be cleaned in-between or at the end of the manufacturing process.

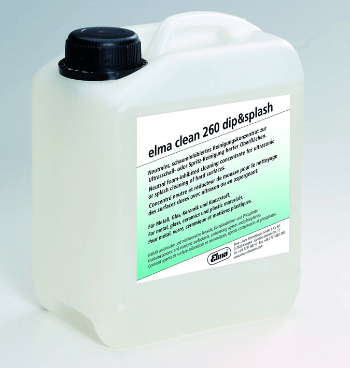

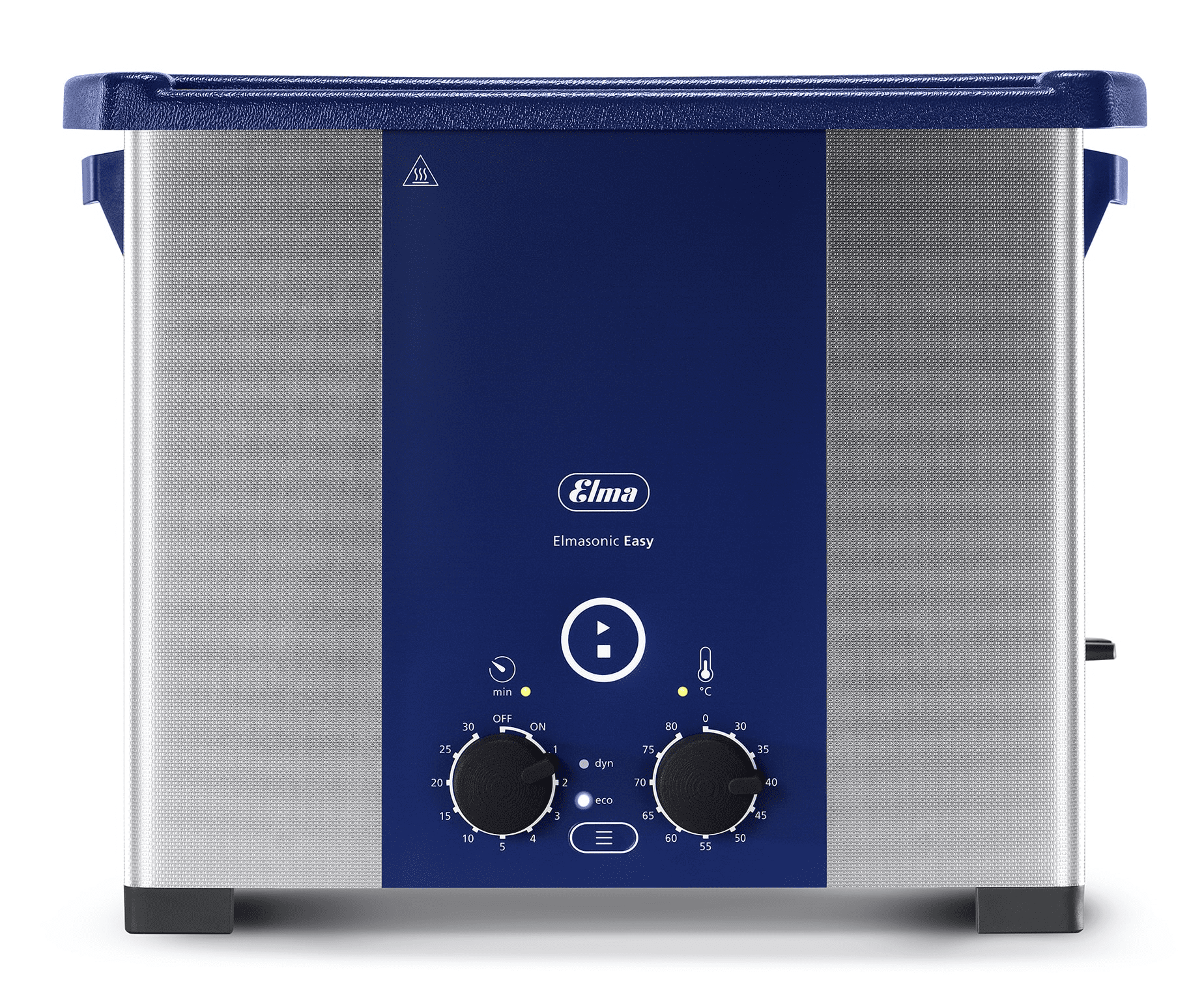

The technologies ultrasonic cleaning and steam jet cleaning from Elma can make a special contribution here. Both cleaning procedures have the big advantage that all places of the instrument or implant are reached and are thus also cleaned in places which are difficult to access.

As requirements can vary greatly depending on the product, Elma provides modular and customer-specific ultrasonic cleaning systems with integrated passivation for pre-, intermediate and final cleaning. Peripheral equipment for ultrasonic bath care ensures optimum cleaning conditions and durability of the cleaning systems. For smaller quantities of implants or surgical instruments, the Elmasonic ultrasonic serial devices can be used. We complete our range with cleaning chemicals developed specifically for medical products and produced by us.

Knee Joints: A perfect surface extends the life of replacement joints. Especially when treating the complex surface geometry of a knee joint, it is important for the material to be removed evenly during grinding and polishing, in order to ensure a perfect fit. The contact surfaces of knee implants must be homogeneous, precise and very smooth. With drag finishing machines Ra values of 0.01 μm can be achieved.

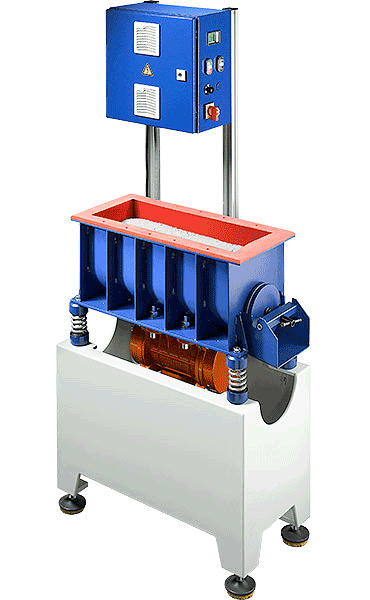

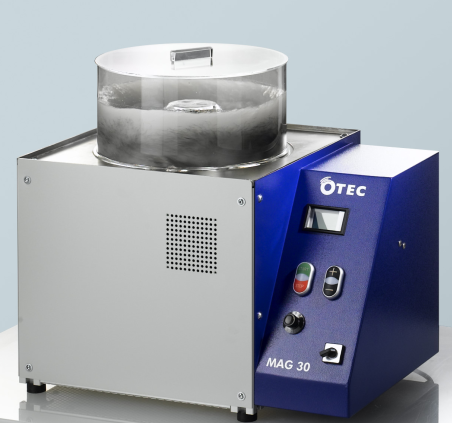

Surgical fasteners, Bone screws, Bone plates, Milled parts, etc.: Best results for bulk items processed in CF disc finishing machines from OTEC. In order to obtain a good fit, unrounded but bur-free edges are required as far as possible. A smooth, polished surface is conducive to easy insertion and removal. Furthermore, the smooth surface simplifies the process of disinfection immediately before use. OTEC has developed a way to fulfil all three requirements in a single process. By using a disc finishing machine it is possible to create a smooth, highly polished surface without any significant edge rounding. After this single-stage process the workpieces are light in colour, have a pristine finish and exhibit a much higher quality. In this process Ra values of 0.03 µm can be attained. In contrast to this, bone plates usually require a considerable degree of edge rounding and the surface should be as smooth and homogeneous as possible. Here, too, a disc finishing machine is used, albeit with different process parameters. This enables all traces of stamping and chip removal operations to be removed in a very short time and produces a smooth, high-quality surface.