The quality of stamping, forming and cutting tools can be improved considerably by finishing the workpieces in DF and SF machines from OTEC. Defined edge rounding dramatically increases the life of cutting tools, as a rule by a factor of three. The OTEC process not only rounds the edges but also smooths the surfaces considerably. This significantly reduces chipping and improves chip flow. The friction acting on PVD and DLC coated workpieces can be reduced dramatically by means of a short finishing process which thereby significantly reduces wear. With forming tools, Ra values of up to 0.02 µm can be achieved and the percentage of contact surface greatly increased. Special polishing processes largely prevent corrosion at the tool holder, so that no further anti-corrosion treatment is needed for several months.

Carbide Cutters, Thread-Cutting Dies, Inserts and small broaches:Processing in a drag finishing or stream finishing machine reduces the risk of chipping. Precision rounding of the cutting edges and polishing the chip flutes increases tool life and improves cutting performance.

Tool Mounts, Hollow taper shank tool holders: Polishing greatly improves the appearance of tool holders. It also largely prevents corrosion at the holder.

PVD and DLC Coated workpieces: Stamping, forming and cutting tools are often coated with a carbide material in order to reduce wear. As a result, droplets can form on the surface of the tool. The drag finishing process selectively removes these droplets. Lubricant can be retained in the tiny holes and depressions left behind. This gives an improved film of lubricant on the surface of the tool, resulting in much less friction and reducing wear dramatically.

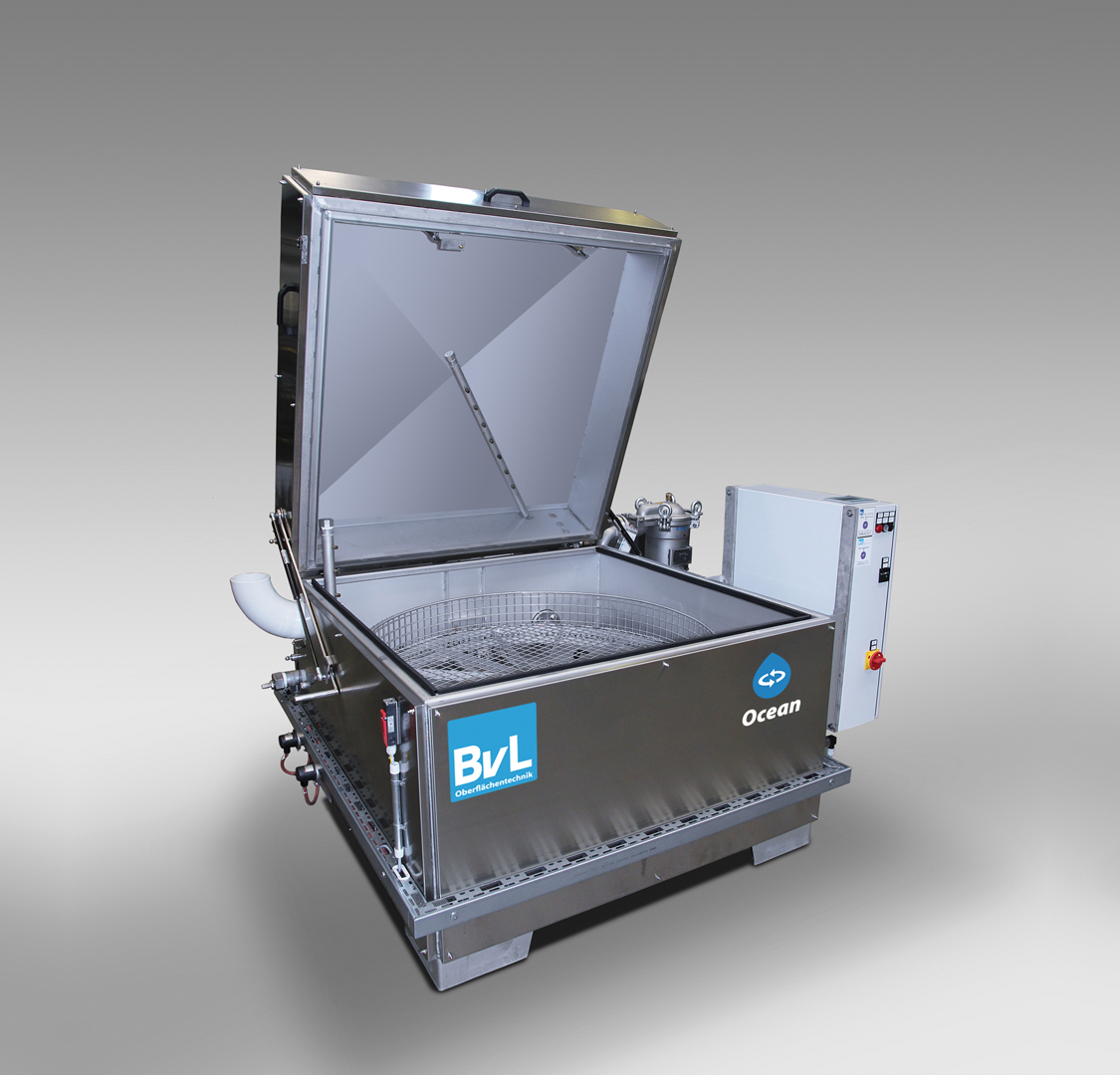

Finishing of Stamping and Forming Tools: The quality of stamping and forming tools can be improved considerably by means of the OTEC finishing process. Surface finishing lowers the coefficient of friction and thereby reduces wear at the surface of the tool. Polishing the forming surfaces can considerably increase the life of stamping and forming tools and improve tool performance. Smoothing the roughness peaks reduces the forces required and gives better flow characteristics during forming. In order to ensure that the quality of tools remains constant, regular repolishing is absolutely essential. Finishing in OTEC machines not only cuts down on expensive manual finishing work, but also delivers absolutely reliable and reproducible results.

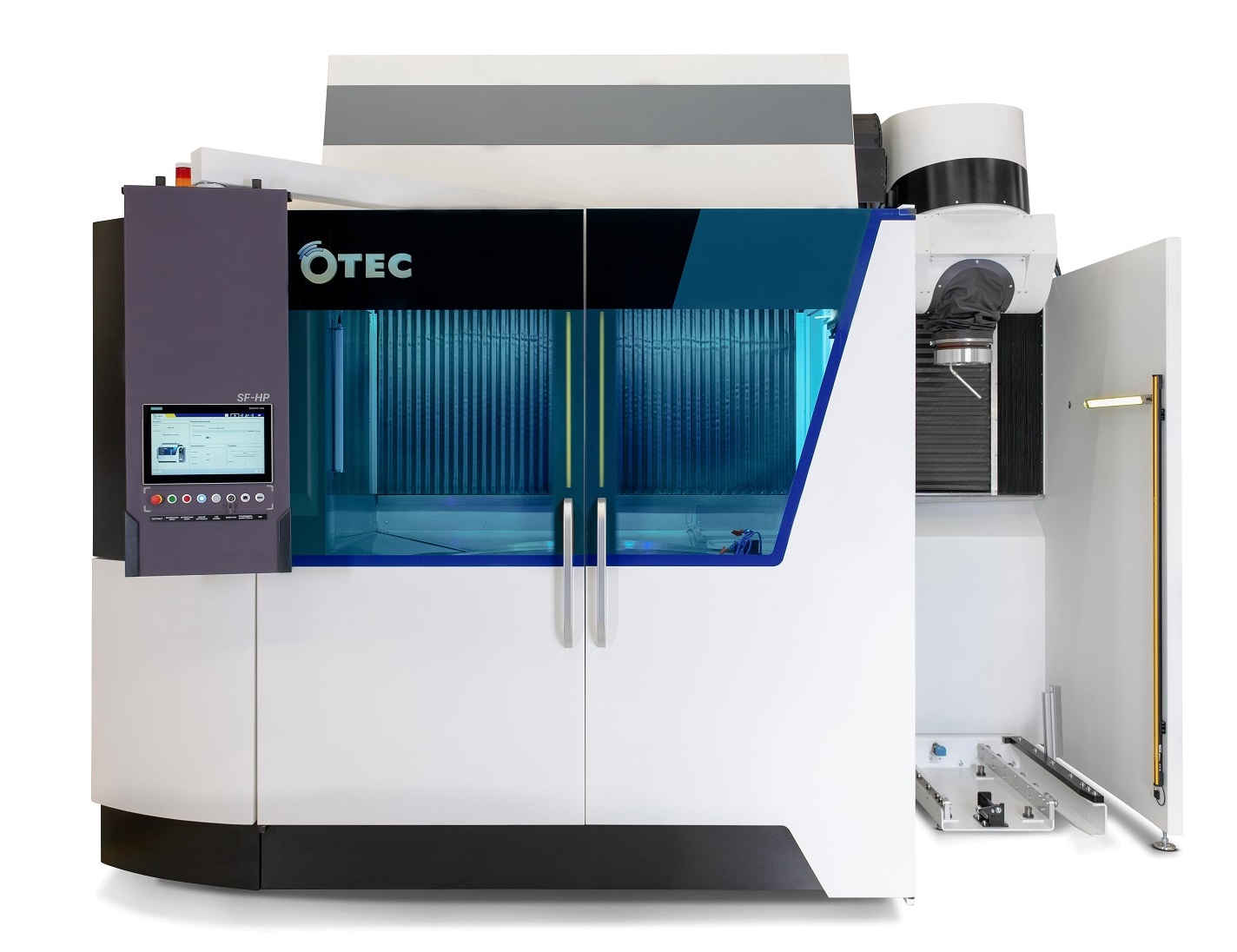

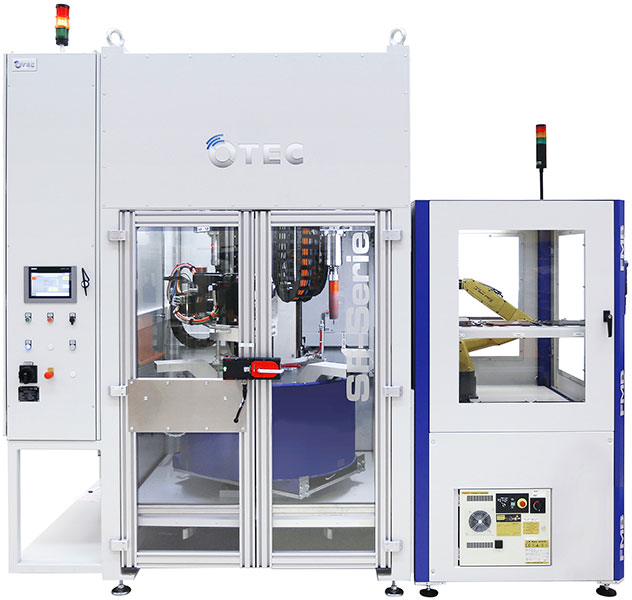

Inner Forming Dies: A smooth surface produces less friction, and therefore less wear. The forming tools' service life can be increased by polishing the forming surfaces. A perfectly shaped and smoothed die also benefits the processing result on the workpiece. Inner forming dies can be polished rapidly with stream finishing technique. Various machine models for surface finishing are available depending on requirements and quantities.

Can Seamer: Polishing and smoothing of the grooves for improved flow characteristics during forming. Polishing and repolishing has previously been carried out mainly by hand. Surface finishing in the Stream finishing machine not only cuts down on cost-intensive manual work, but also creates a surface of the highest quality with absolute reliability. Extremely fine surfaces can be obtained, even in small grooves or flutes. The amount of material removed from the forming surfaces during polishing is reduced to a minimum.

Tap: Deburring between the thread profile and the chip flute and defined rounding of the cutting edges for extended tool life and improved adhesion of the subsequent coatings. In Stream finishing machines with Pulsfinish taps can be deburred and rounded reliably, quickly and economically.

Thread Formers: By smoothing the tools' surface, the deformation forces can be reduced by about 60%. A smooth surface reduces the formation of material in the forming grooves and reduces the friction between the tool and the material to be deformed.

Tool Bodies: For surface processing, two main tasks are involved in the production of cutter bodies: Deburring after milling and polishing after hardening and grinding. The reliable removal of burrs is important for optimum fit of the inserts on the cutter body. A burr-free and flat support surface is important for stability during the cutting process and prevents chipping of the insert. The subsequent polish removes the oxide layer formed during hardening, thereby improving the visual appearance and upgrading of the part for sale. However, the perfectly polished, smooth surface does not only affect the appearance of the tool but also affects the functionality. Due to the polish the surface is closed, compacted and significantly smoothed. The extreme smoothness offers less attack surface for corrosion and ensures a better chip flow in the flute. A specific surface treatment can thus significantly increase the efficiency of the tools.