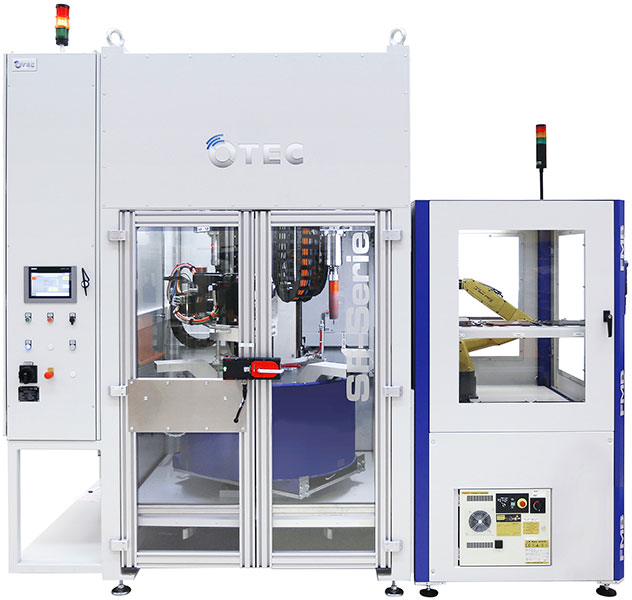

The SF Automation series offers deburring, rounding and smoothing in a single processing stage, in a very short time and without detriment to the contours of the workpiece. Path-controlled motion enables specific areas of a workpiece to be processed more intensely. Because of the tremendous processing forces involved, the SF Automation provides fast and economical finishing and guarantee absolutely reliable processing results.

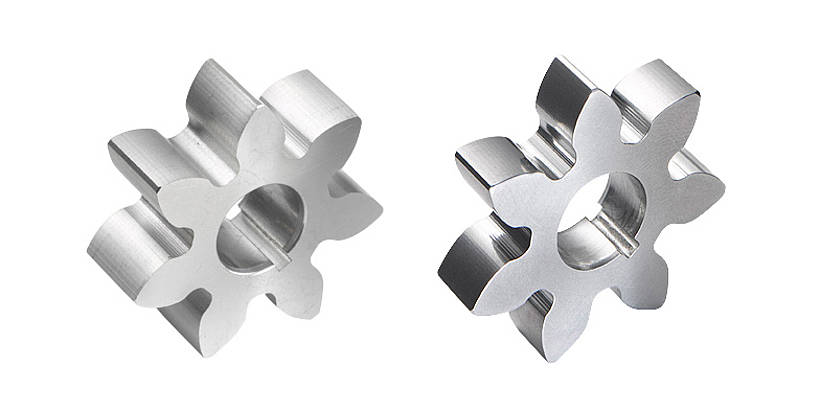

The SF Automation series of machines can optionally be equipped with pulse finishing and because loading is carried out automatically, they are suitable, among other purposes, for production lines with a predefined cycle time. Depending on the requirement profile, the machines can be pre-equipped automatic loading or optionally equipped with integrated automatic loading. The modular design of the machine means that it can easily be adapted to the cycle time. This enables the SF Automation to be easily incorporated into a production line as an integral component of the line. Typical applications for the SF Automation series include deburring, rounding, smoothing and polishing of camshafts and components with complex geometries such as thread-cutting dies and fuel injectors.

- Automatic workpiece loading

- Wide range of finishing applications (several processing steps in a single process)

- Selective finishing of individual workpiece surfaces

- Tremendous processing forces through high stream speeds

- Short processing times

- Extremely economical

- Ideal for integrating into a production line

- Number and design of workpiece holders can be customized to suit requirements

APPLICATIONS

VIDEOS

TECHNICAL REPORTS AND NEWS

PUT US TO THE TEST

We can try our solutions to your surface finishing and cleaning problems together. We will evaluate the results and make suggestions about your problems on surface finishing and cleaning processes.

Send us some sample, we will transmit you the results and our suggestions in the form of a process report.