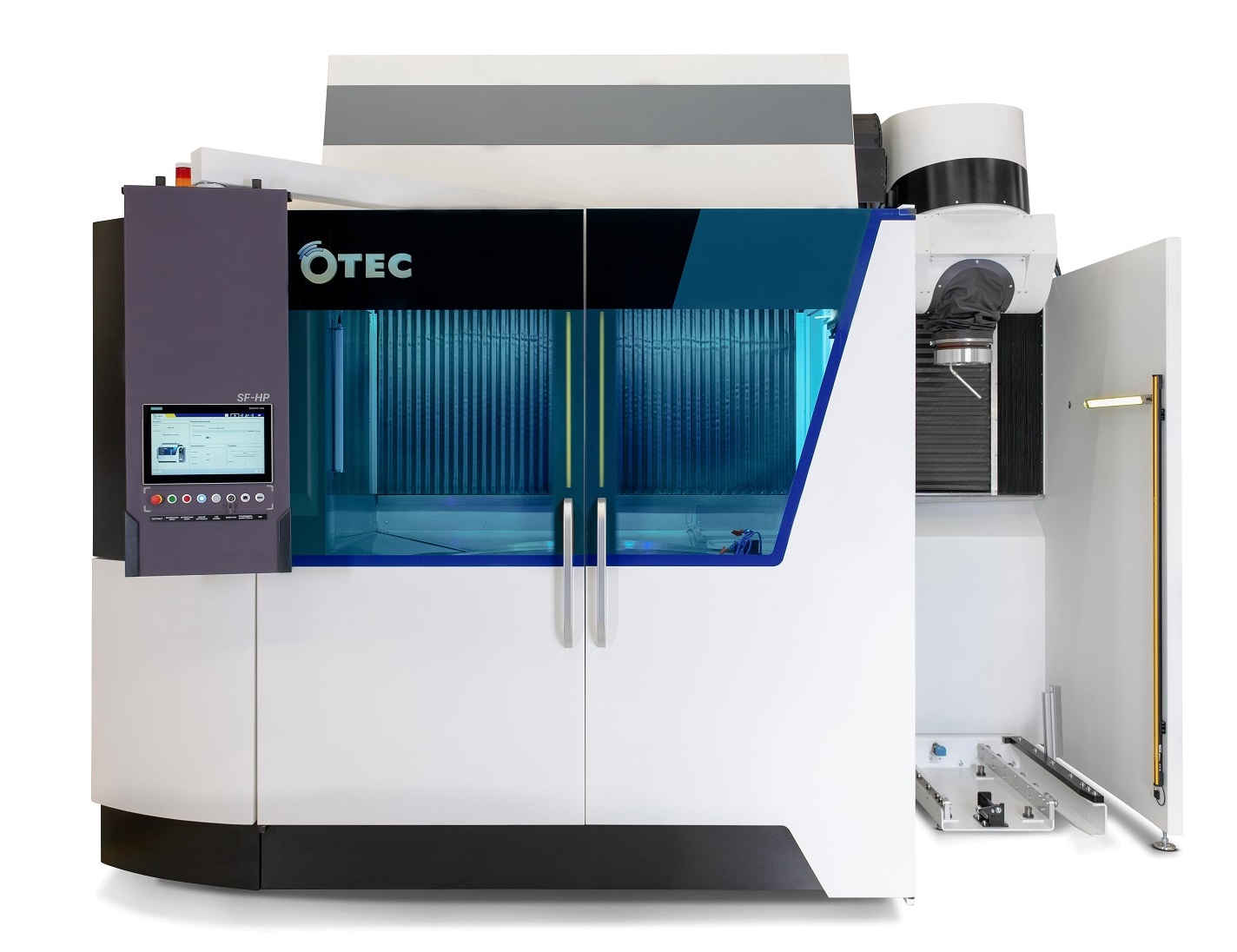

SF technology, also known as stream finishing, gives rise to an innovative new generation of mass finishing machines. The SF process offers very short finishing times, is easy to automate and at the same time produces highly consistent and reliable results. The differences to other technologies lie in the tremendous processing forces harnessed by the machine. This enables material to be removed more selectively and faster than with any other surface finishing system. The SF was specially designed for applications for which no satisfactory process previously existed, and specifically for applications which call for the highest possible surface qualities in the smallest of geometries. It fulfills the requirements of a wide range of finishing tasks from deburring and mirror-finish polishing to smoothing and polishing, as well as the edge rounding of cutting tools.

The SF machines are especially suitable for the finishing of stamping, forming and cutting tools, for finishing components in the automotive sector and for achieving perfect surfaces in the aerospace industry.

PULSFINISH TECHNOLOGY

Stream finishing units can optionally be equipped with PULSE FINISHING technology. The principle of the new PULSE FINISHING process is based on the precisely defined and rapidly alternating relative motion between media and workpiece. This patented pulse drive was specially developed for the requirements of the automotive sector and the modern toolmaking industry. The PULSE FINISHING process enables the extreme requirements of large-scale series production to be consistently met in terms of process reliability, speed and finishing quality. For example, it is possible to deburr, round and smooth surfaces from Rpk 0.2 μm to Rpk 0.1μm in less than a minute and in a single processing stage. This achieved without adversely affecting the contours of the workpiece.

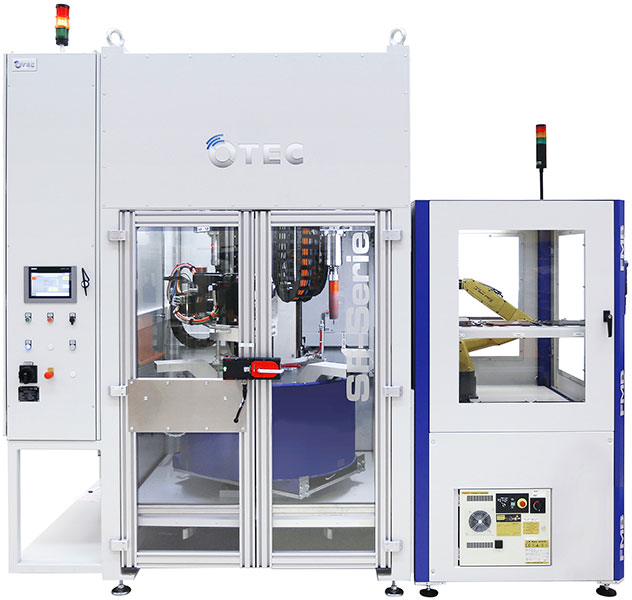

Fully automatic process

Precisely programmed motion cycles

Can be integrated into the production line

Several processes in a single processing stage