For some years now, cleaning optical components has emerged as a special requirement in parts cleaning.

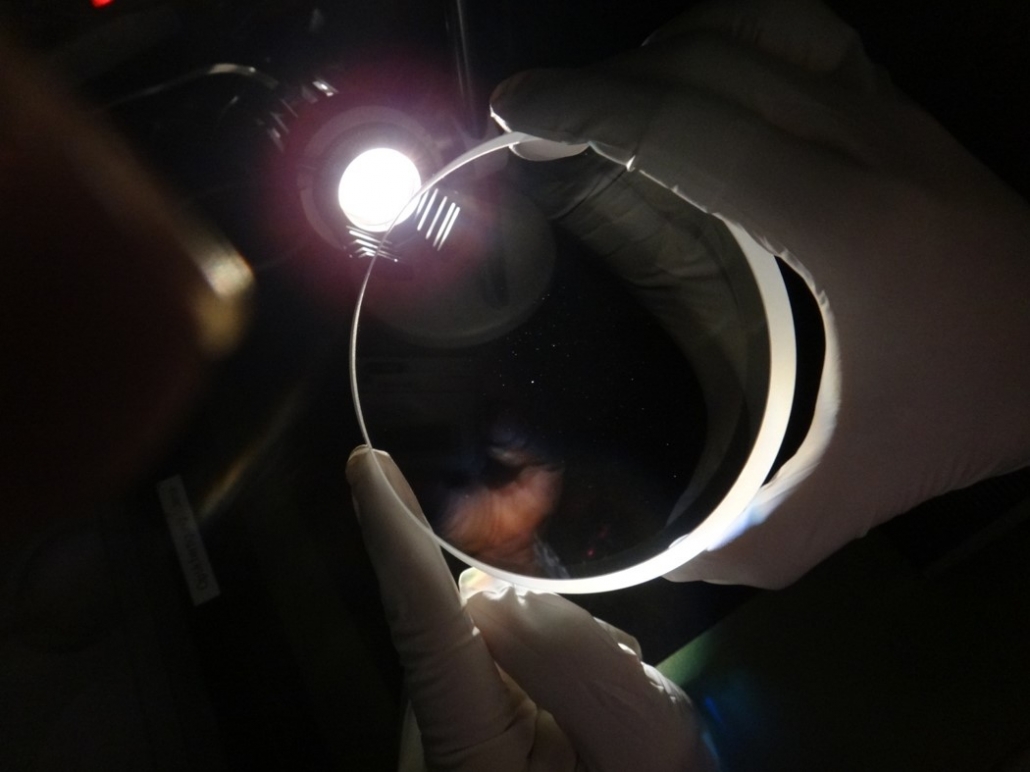

This is mainly because the components are very sensitive materials. The basic building material is usually glass. Apart from “treatment errors” that would lead to a “damage” to the surfaces, there is also the risk of corrosion damage from the cleaning process.

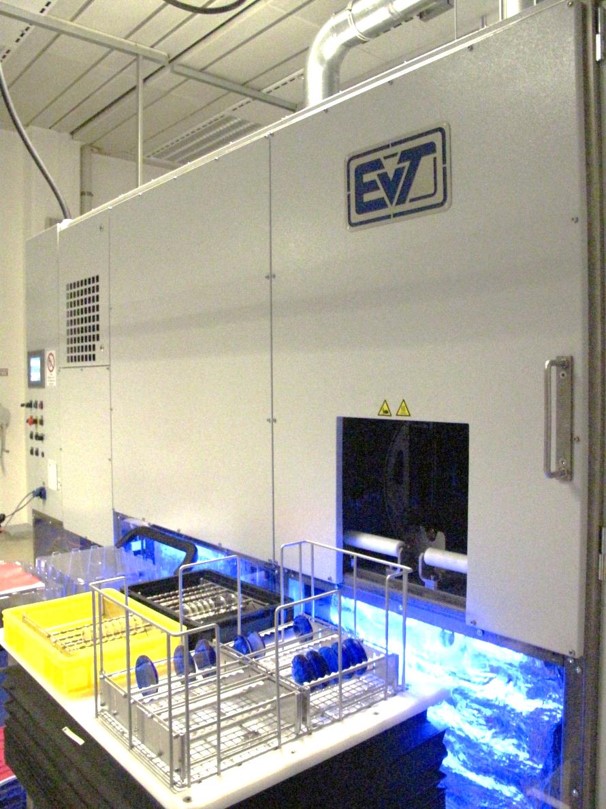

EVT offers a process technology that specifically enables the effective pre-cleaning of these sensitive components.

Protective varnishes, putties, centering oils and other auxiliary substances are applied during production process of prisms and lenses. These must be removed at the end of the manufacturing unit.

Cleaning by EVT systems precedes the final fine cleaning and consequently usually relieves them.

“In order to achieve the technical cleanliness that our customers need for their quality products, we have developed a special process. It differs from the conventional procedure in several ways, ”explains managing director Costa Burkhardt.

On the one hand, a special chemistry is used that is tailored to the optics. In contrast to cleaning with water, it significantly reduces potential glass corrosion. The closed procedure in turn enables higher temperatures during the cleaning process. Sensitive parts can be cleaned more gently but also more effectively.

Contact times become superfluous

“Long exposure times, which are otherwise necessary to reliably remove the contaminants, are now superfluous,” Burkhardt continues. “We can save the customer time that significantly speeds up his production process. Overall, there is a relief in terms of time and costs. Also a qualitatively reliable and thus overall efficient process.

For our customers, this means a significant improvement in all the metrics relevant to them. ”

EVT systems are always manufactured individually according to the needs of the customer. Both the spatial conditions of the future location are taken into account, as well as the sensitive matrix of interdependent parameters:

Material,

Charge times

Batch sizes

Component geometry,

Type and degree of pollution,

Requirement for the cleaning result and

process steps following cleaning.

This makes EVT cleaning systems reliable and popular components in the production chain of well-known manufacturers of optical components.

PUT US TO THE TEST

We can try our solutions to your surface finishing and cleaning problems together. We will evaluate the results and make suggestions about your problems on surface finishing and cleaning processes.

Send us some sample, we will transmit you the results and our suggestions in the form of a process report.