Safe and efficient drying of parts with warm and cold air

Elma Dry drying units are available in 3 sizes (30, 120 and 300) and designed for use in production, workshop and service. After ultrasonic cleaning, the parts are first rinsed in the basket with municipal water and then conveniently placed in the Elma Dry drying unit.

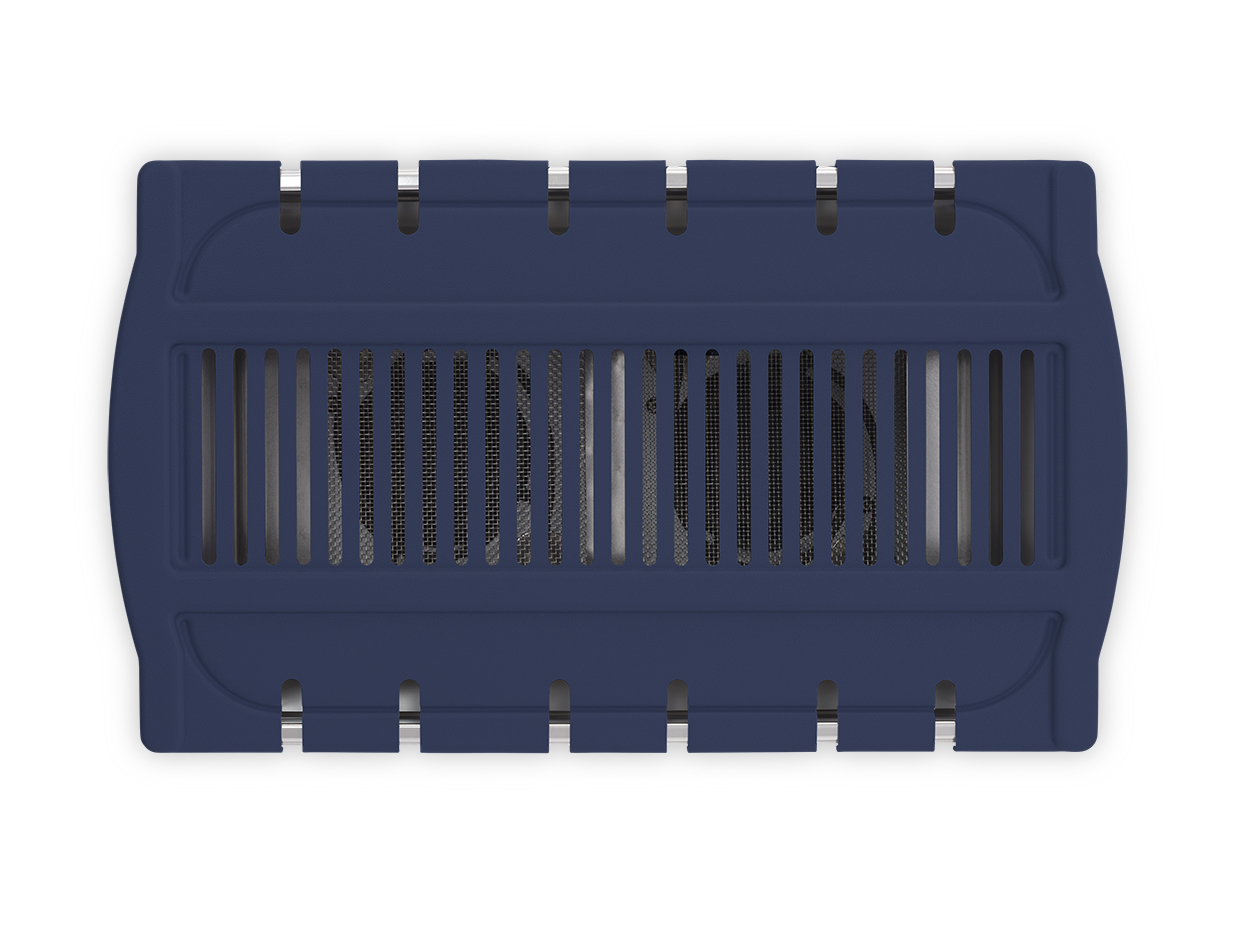

Fitted with cold and hot air blower (70 °C), sensitive parts can also be dried gently. In cold air operation, the parts to be dried can also be cooled quickly. The hot air function is activated while the cover is on. The cover has ventilation slots, ensuring that maximum air turbulence is produced and the moist air is conducted to the outside. At the same time, the cover reduces energy consumption.

The dust filter on the underside is replaceable and prevents re-soiling of the cleaned parts by the dust in the room air.

Elma Dry units are very user-safe thanks to the safety shutdown upon reaching the limit temperature.

APPLICATIONS

TECHNICAL FEATURES

| Elma Dry 30 | Elma Dry 120 | Elma Dry 300 | |

| Tank labour capacity (l) | 1.9 | 9.0 | 20.6 |

| Heating power (W) | 480 | 550 | 1100 |

| Temperature max. (°C) | 70 | 70 | 70 |

| Unit out diimensions W/D/H (mm) | 300/186/219 | 362/285/322 | 568/347/322 |

| Tank inner dimensions W/D/H (mm) | 240/137/100 | 300/240/200 | 505/300/200 |

| Max. basket loading (kg) | 1.0 | 7.0 | 12.0 |

| Basket inner dimensions W/D/H (mm) | 216/106/48 | 276/126/76 | 420/250/300 |

| Weight (kg) | 3.6 | 6.1 | 10.2 |

PUT US TO THE TEST

We can try our solutions to your surface finishing and cleaning problems together. We will evaluate the results and make suggestions about your problems on surface finishing and cleaning processes.

Send us some sample, we will transmit you the results and our suggestions in the form of a process report.